Project Overview:

In the tyre manufacturing industry, product quality is of utmost importance. To ensure that the aesthetic and functional performance of tyres is maintained, inspection is carried out before dispatch. The present inspection is carried out manually by operators who inspect around 750 tyres every day. However, around 1% of defective tyres are not detected and enter the market, meaning thousands of defective tyres in the market every year. This is not acceptable for tyre manufacturers, who value customer satisfaction and product reliability.

Problem Statement:

This refers to inefficient, time-consuming, and prone to errors manual inspection processes in the manufacture of tyres. Although the trained employees are very efficient, the prevailing system is unable to notice all the defects, with a high percentage of such defective tyres being released to the customers. An automated inspection system would increase accuracy, reduce inspection time, and ensure superior quality assurance.

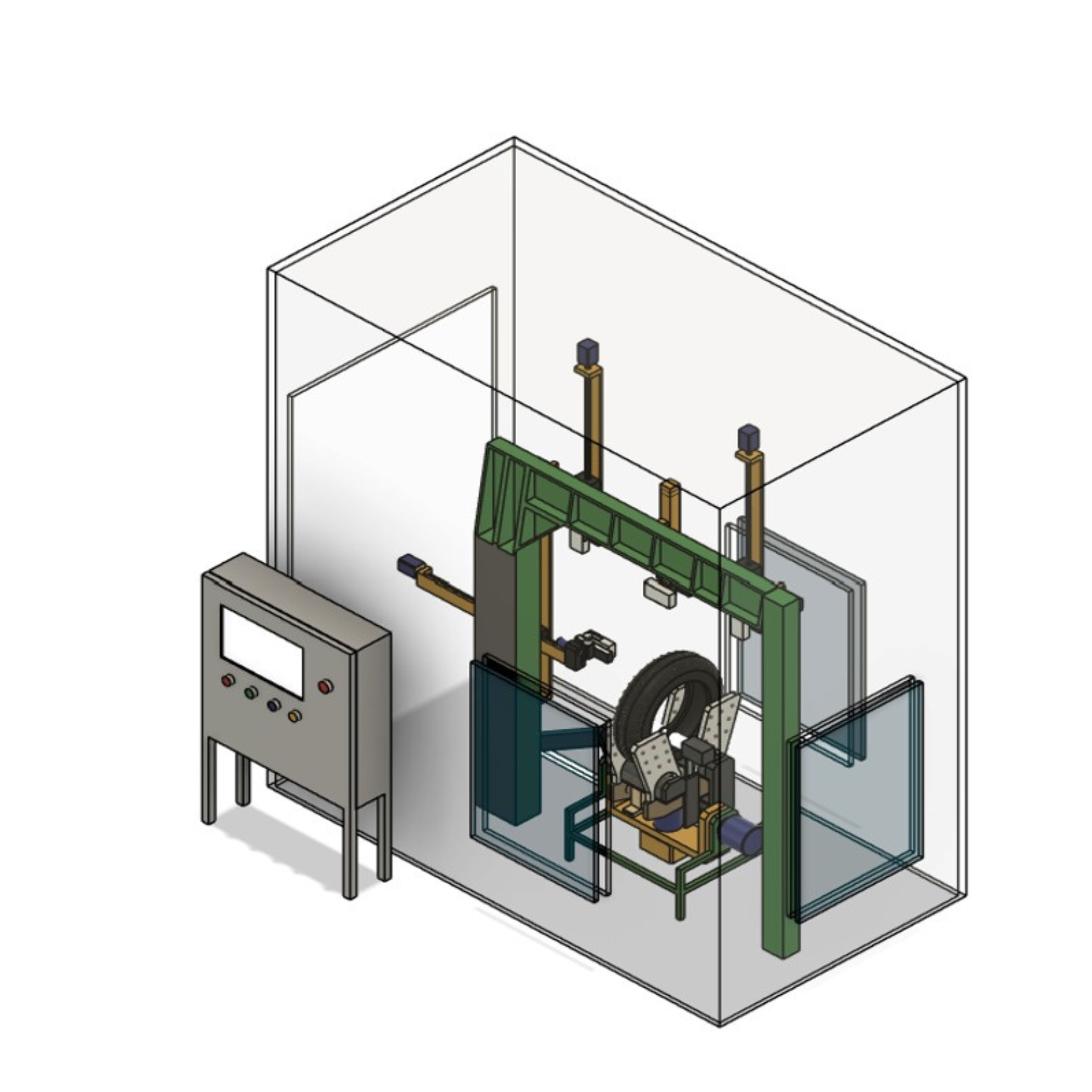

Proposed Solution:

The following is an AI/ML-based solution for addressing these challenges. This system uses the combination of advanced technological approaches like laser triangulation scanning and machine learning techniques in order to inspect the tyre thoroughly.

Key Components:

- Laser Triangulation Scanning: In this technique, lasers scan a surface of the tyre; thus, data of high resolution can be obtained at any part of the tyre.

- Machine Learning Algorithms: The sensor-recorded data is fed into machine learning and deep learning algorithms that can identify defective tyres in about 30 seconds.

- Scalability: The solution can be easily scaled to identify defects in tyres of different types and sizes, making it versatile for various manufacturing needs.

Implementation:

- Real-Time Inspection: High-resolution sensors and lasers scan every tyre in real time, detecting defects such as cracks, bulges, and surface irregularities.

- Data Processing: The gathered data is processed using ML/DL algorithms to precisely identify and classify defects.

- Automated Decision Making: The system provides immediate feedback, thus enabling quicker decision-making and corrective actions.

Impact

The AI-based automated tyre inspection system significantly improved as follows:

- Increased Accuracy: The system was able to attain higher precision in detecting and classifying defects, thereby reducing the number of defective tyres reaching the market.

- Efficiency: Automation reduced inspection time and increased the throughput of inspected tyres.

- Quality Assurance: Continuous data analytics allowed better process refinement, ensuring consistent product quality and reliability.

This advanced AI solution transformed the tyre inspection process, ensuring superior quality control, reduced operational costs, and enhanced customer satisfaction.